Automatic Wire Stripping and Ferrules Crimping Machine KS-T881T provides efficient processing of loose wire end sleeves/ferrules with plastic collars in different lengths. The ferrules are automatically fed by vibration plate, stripping and crimping in one work step which greatly improves the crimping efficiency of the ferrules. The feeding guide rail is easy to adjust. One machine can be used for terminals of different sizes.

Easy to program and operate;

Excellent price/performance ratio;

With sensitive pneumatic induction control, crimping quickly;

Feeding of vibration plate, wire stripping, terminal wearing and crimping in one work step;

High level of reliability due to maintenance and wear-free components;

No special tooling for stripping length adjustment required. Robust & reliable, high working efficacy;

Inductive switch, safer and more convenient;

Place wire with bell mouth, fully sealed shape design, safe operation, reduce the possibility of injury, and ensure a more beautiful appearance under the premise of safety;

Operation with touch screen, electric adjustment, save the set parameters and can be directly called;

Automatic feeding, labor-saving and time-saving, and simple adjustment is needed for changing specifications, which is convenient and quick;

Different crimping specifications, there is no need to replace the crimping applicator.

Applicable Wire Type: BVR wire 0.5、0.75、1.0、1.5、2.5、4.0 mm²

Stripping Length: 8~16mm

Applicable Terminal: Tubular pre-insulated terminal

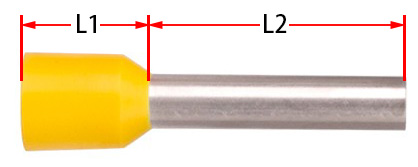

Terminal size: L1≤7.5mm, L2≤10mm

Crimping Shape: Quadrilateral crimping (imitating square)

Detection Items: Lack of terminal detection, right side safety door detection

Working Mode: Manual/Automatic triggering

Production Capacity: 2.5s/pcs (Considered as a single cycle of the machine)

Function: Cut & Strip & twist wire and crimp terminal all in one time

Control Mode: Human machine interface, electronic control, pneumatic control

Power Supply: AC 220V/50Hz, single phase, 10A, internal power supply DC24V

Air Supply: 0.6~0.8Mpa (Stable, clean and dry air source)

Dimension (L×W×H): 390×450×430mm (protrusions are not included)

Net Weight: 40Kg

Note:

The above specifications are for reference only. In the case of extremely hard, tough wires, processing may not be possible even within the cross section range. In case of doubt, KINGSING will be happy to provide processing samples of your wires.

Conforms to the relevant CE directives on machine safety and electromagnetic compatibility.

Product Updates: Images and videos displayed may differ from current products due to ongoing design improvements and updates. The actual delivered product shall prevail in case of any discrepancy.

Optional Accessories: Some accessories and components shown in product photos/videos are optional configurations and not included in the standard package. Please order these items separately if required.

Technical Parameters: Specifications are for reference only. Equipment suitability depends on actual working conditions, not just parameter comparison. Please consult us to confirm compatibility for your specific application.

English

English