This advanced wire stripping and ferrule crimping machine is specifically engineered for efficient processing of tubular insulated terminals. The integrated design combines wire stripping, conductor twisting, terminal insertion, and crimping operations into a single automated workflow, significantly reducing processing time and labor costs.

The machine features a built-in miniature vibrating plate that automatically feeds terminals to the crimping position, eliminating manual terminal handling. Operators simply insert the wire end into the working position, and the machine automatically completes the entire sequence: stripping the wire insulation, twisting the copper conductors, threading the terminal, and performing precise crimping with quadrilateral compression.

Equipped with an intuitive color touch screen interface, the machine allows direct parameter adjustment for stripping depth, stripping length, and twisting force. The programmable memory function stores processing parameters for different wire and terminal combinations, enabling quick changeover between products with one-touch parameter recall.

This versatile machine accommodates multiple terminal sizes through simple tooling changes, making it ideal for electronics manufacturing, automotive wiring applications, and industrial cable assembly operations. The automated process ensures consistent crimping quality while preventing wire overturning and maintaining optimal conductor-to-terminal connections.

| Applicable Wire Size | 0.25~4.0mm² |

| Applicable Terminals | Tubular insulated terminals, ferrules |

| Stripping Length | 0~12mm |

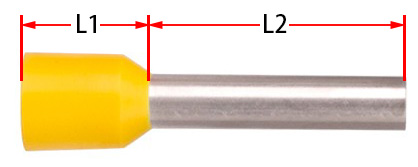

| Terminal Size | L1≤7.5mm, L2≤12mm

|

| Minimum Wire Length | 40mm |

| Crimp Shape | Quadrilateral |

| Production Efficiency | 1000~1200 pieces/hour |

| Working Voltage | 220V 50Hz (customizable) |

| Rated Power | 500W |

| Air Pressure Requirement | 0.5~0.8Mpa |

| Net Weight | 68kg |

| Dimensions | 430×505×425mm |

Product Updates: Images and videos displayed may differ from current products due to ongoing design improvements and updates. The actual delivered product shall prevail in case of any discrepancy.

Optional Accessories: Some accessories and components shown in product photos/videos are optional configurations and not included in the standard package. Please order these items separately if required.

Technical Parameters: Specifications are for reference only. Equipment suitability depends on actual working conditions, not just parameter comparison. Please consult us to confirm compatibility for your specific application.

English

English